Services

We are capable of serving all kinds of rotating and reciprocating machinery used in the process plant including its associated pipework, structure, and foundation.

Machinery Diagnostic

-

on site/remote rotating and reciprocating machinery malfunction diagnosis

-

single / multiple planes field balancing

-

pre and post machinery outage support

-

machinery vibration and condition monitoring system troubleshooting

-

long-term predictive maintenance (PdM) services contract

-

reciprocating compressor condition monitoring and diagnosis

- hydroturbine-generator condition monitoring and diagnosis

- root cause failure analysis (RCFA)

- performance monitoring and diagnosis

- Structure vibration analysis

- piping vibration analysis

- pulsation measurement and study

- flow/acoustic induced vibration

- Low speed bearing monitoring solution.

System & Instrumentation

-

Transducer Calibration

-

System Loop Test

-

Design, Installation, and Commission machine condition monitoring system

-

End user representative for FAT/SAT witness.

-

Budgetary based MMS instruments selections

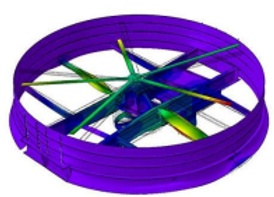

Computer Aided Engineering

-

rotordynamics modeling and analysis

-

torsional vibration modeling and analysis

-

static/dynamic pipe stress analysis

-

finite element analysis (FEA) and computational fluid dynamics (CFD) analysis

-

process flow modeling and simulation

- expert witness factory acceptance test (FAT) of machinery, condition monitoring system, or shop balancing works

Technical Training

-

vibration analysis of turbomachinery

-

machinery behaviors and malfunctions

-

machinery vibration and balancing

-

modal and operating deflection shape (ODS) analysis

-

rotordynamics modeling & analysis

-

static/dynamic pipe stress modeling & analysis

-

vibration motoring system operating and maintenance

-

ISO vibration analyst courses